Got Robots? Working Side-by-Side in Manufacturing Precision Metal Components and Assemblies

Remember watching The Jetsons, or Sci-Fi movies, and wondering if there would ever be a time when it was the norm to have robots at home or working side-by-side with people as coworkers?

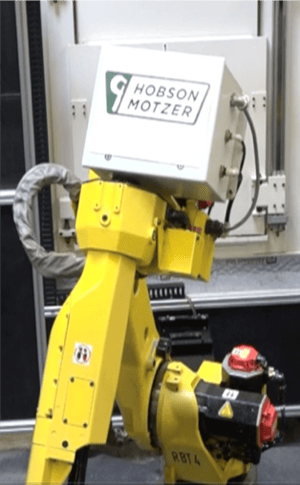

Well, here at Hobson & Motzer, we may not be hanging out at the water cooler with them like George  Jetson, but we—indeed—have robotic coworkers! We employ more than 40 advanced robotic units in automated manufacturing cells. We thrive with what was once considered a distant possibility.

Jetson, but we—indeed—have robotic coworkers! We employ more than 40 advanced robotic units in automated manufacturing cells. We thrive with what was once considered a distant possibility.

A core focus at Hobson & Motzer is advancing technology. We recognize the importance of consistently meeting the challenges of manufacturing parts, components, and assemblies in the most precise, efficient, way possible. One way we are able to meet, and typically exceed, our customers’ expectations is by being an early adopter of technology. Developing expertise and capability ahead of the curve allows us to drive value and meet performance, quality, and service levels. And we proved this again by charging full speed into the Robotic Age nearly 10 years ago, when companies’ manufacturing automation was still akin to The Jetsons for non-automotive companies.

Automated Production Cells

Automation technology has come a long way over the past 10 years, as robotics manufacturers drove the technology to new heights and scaled up. Access and availability to robotic machines with a diverse range of capabilities and configurations are in reach of more manufacturers than ever before. Where they were once caged units, for safety, it is now possible for humans to collaborate with robots, or co-bots as they are aptly referenced. These are designed to work with and assist human operators to improve efficiency, speed, and accuracy, and reduce machine down time. For example, what would take an operator 2 minutes to complete, can take a robot less than 1 minute, freeing up the operator to perform more critical operations. Robots can also handle the dangerous, repetitive, and mundane tasks, which protects our workforce.

Automated cells can take many forms, with one or more robots carrying out duties that make everything work together effortlessly. Utilizing robotic technology for inspections, machine tending, material handling, and multiple machine management improves consistency and quality and yields a faster return on investment.

Dedicated Teams

It is common to outsource automation for design, implementation, service, and maintenance. Hobson & Motzer entered into this technology early and developed internal expertise. That jump on the technology created a natural advantage and led to what is now a dedicated core team of R&D/automation technicians and engineers in both our main plant and in our advanced manufacturing facility.

We take advantage of automation because it improves our performance and efficiency; we support automation technology and take it to the next level of innovation by keeping our team engaged with what is happening in the robotics industry. We have found great success in employing from technical schools—when blended with our experienced personnel internally, it forms a formidable team with which to advance technology and equipment. Our team uses available technology to sharpen their skills in critical thinking, decision making, and problem solving. In order to effectively collaborate with robots, our team has the skills that integrate people, processes, data, and devices to understand how new technologies can improve manufacturing.

Use of robotic automation won’t eliminate manufacturing jobs, contrary to popular belief. Automating the  repetitive, monotonous, and dangerous tasks creates more desirable jobs, such as engineering, management, and equipment maintenance.

repetitive, monotonous, and dangerous tasks creates more desirable jobs, such as engineering, management, and equipment maintenance.

Benefits of Robotic Automation

When using robotics on the production floor, the programmed cells:

- Improve consistency

- Create quality parts

- Ensure repeatability

- Create a more engaged workforce, allowing them to improve on their technical and problem-solving skills

So, while just a few decades ago, robots were relegated to being main characters of science fiction, today they are a reality. As time goes on, they will become smarter, more capable, and able to handle more advanced tasks. And while our robots don’t exactly look human, the future at Hobson & Motzer is bright, as humans and robots work together as colleagues for the continuous improvement of manufacturing as a whole.

We work extensively with the medical device industry and other quality-critical markets where innovation and precision requirements depend on advanced technology to delivery uncompromising quality every time. We—and our robots—are capable and dependable manufacturing partners and look forward to helping you with your medical device parts and components. Contact us now to find out how we can make your next project a success.